I am an Essex based WI approved speaker and give talks and demonstrations on an eclectic mix of subjects.

Speaker | Artisan Blacksmith | Beekeeper

As we come towards the end of September we also mark the end of the beekeeping year. The wet Spring was a real challenge to gardeners and beekeepers alike. Plants and insects just seemed to sit and wait for signs of Spring, but they never really came. The impact on pollinators and insects in general has been much reported, with record low numbers of butterflies for example and, from our own experience, a very slow build up of bee colonies. Even when a form of summer arrived it was clear that colonies were struggling. As a result, honey stores are low, to the extent that we are leaving the majority of this year’s honey crop with the bees to ensure they are as strong as possible and ready for the coming winter.

There was however a bright end to the summer season. That came with the fields of beautiful blue borage.

Borage honey remains my favourite single crop honey. Visually it is clear and light, most notable when compared to a regular summer season honey. From a taste perspective it has a lovely light tang to it and due to its composition it doesn’t start to set for upwards of a year. I have it available from my shop here.

It may only be the beginning of March, but the bees are taking advantage of every warm day to get out of the hive.

At this time of year there isn’t much available by way of forage for them, but the odd crocus and primrose flower provides vital pollen, as does some of the early tree blossom. The pollen is used by the bees to produce ‘brood food’, fed to the developing bees which will grow into Spring foraging bees.

At this time of year there isn’t much available by way of forage for them, but the odd crocus and primrose flower provides vital pollen, as does some of the early tree blossom. The pollen is used by the bees to produce ‘brood food’, fed to the developing bees which will grow into Spring foraging bees.

These early Spring flights are also important to help the bees with the right conditions to clean out the hive.

It is a lovely sight after the long winter months and a true sign of the warm days to come.

There are still a few days to order honey in time for Christmas. I am currently using Tracked 48 hour delivery services to post out honey so all should be fine up to the end of this week at least.

Whether you prefer the light delicate flavour of borage honey, seen on the right in the picture below, or the depth of flavour in blossom honey, as on the left, the choice is yours.

Along with local honey being that ‘what can we possibly buy for ……….’ present, it is good to remember the positive side to eating local raw honey. Even NICE, The National Institute for Health and Care Excellence have been issuing guidance for years that good local honey should be the first defence against coughs and colds, rather than antibiotics.

Beekeepers have been saying this for decades.

************************************************************************

This week we have been doing our bit to save a colony of honey bees.

We were asked to take a look at a hive left by someone giving up beekeeping with some people who had decided this was their opportunity to become beekeepers themselves.

Its new owners had done all the right things. They had bought new equipment to replace the old dilapidated hive and had joined the local beekeepers association to learn what to do, hence asking us to help.

We found a very small colony on old comb with a disorganised mix of frame types and an area where they had been left to make comb as they wished, which you can see on the far right of this picture. The bees we found looked healthy.

The problem was that we couldn’t inspect the bees in this wild comb as it was fixed to the box. It was also, of course, where the bees had decided to live.

So what to do?

We cut the ‘wild comb’ out of the box and carefully placed it between some nice new frames in their new, clean hive. As the bees gradually move onto the new comb, the wild comb can be removed. There are only a couple of cups of bees in there, perhaps a few hundred, whereas a full colony should have upwards of 30,000 bees at this time of year. But they have their queen and there is plenty of nectar around so they have a better chance of surviving now.

This picture shows what we found once we had cut the comb free from its old box. There is everything a colony needs to survive, only on a very small scale.

Right in the centre is the queen, with her female worker attendants surrounding her.

You can see the pearly white bee larvae in cells around her. These will pupate and be sealed into the cell by the worker bees, creating the domed ‘biscuit’ coloured cells you can see around her. In a few days time new bees will chew their way out of the capped cells and start to contribute to the future of the colony.

For food, you can see the nectar the bees have recently collected glistening in the cells on the left and bottom third of the picture. This will have the water driven off by the bees fanning it and, with a little magic from the bees, will become honey.

Then you can see a band of differently coloured cells, with a matt finish. This is pollen from different flowers and trees. See my previous post about the number of different pollen types found in our honey. The pollen is protein to the bees and is used to feed the young larvae as they develop.

So, these bees have everything they need. It is going to be an uphill struggle for them to grow from such a small colony. But, they have a good home, a queen, and some keen new beekeepers to look after them. All they need now is nice weather and a bit of luck.

I had an interesting follow up question to my last post about raw honey for hayfever. It was a simple question, but not so easy to answer. I was asked how an individual can tell if the honey they see on the shelf is pure, raw and unadulterated?

The easy answer might not be quite so correct. You might imagine that if you buy from a ‘man on the market’ then you take your own chances, whereas if you buy from one of the top supermarkets then you are safe in their buyer’s hands. Wrong.

What about price? I just looked on line and you can buy a 12oz jar of honey from a top 5 supermarket for 75p, and that’s typical. Look closely and it comes from China. Some just say ‘blend of non-UK honey’, but is that a problem?

Well, in 2002 all Chinese honey was banned from Europe because it contained illegal levels of antibiotics. Then in 2010 honey from India was banned by the EU for the presence of antibiotics and lead.

In 2016, countries previously without any significant honey production suddenly became major exporters of honey. Honey from countries like Vietnam was siezed and found to be Chinese honey.

More recently the EU has launched a campaign to fight off adulterated honey flooding the markets. As reported in the Financial Times just a few days ago:

“The drive by 20 member states, led by Slovenia, to tighten regulation against what one official dubbed “honey laundering” follows a European Commission study that found a surge in fraud. Almost half of the honeys surveyed broke EU rules, with ingredients such as sugar syrups, colourings and water, according to findings published last month.”

So, surely if you just buy from your ‘Top 5’ supermarket they will have done all the tests to make sure you have pure 100% honey in that jar you have just purchased for, erm 75p?

Perhaps not if you read this report that nearly half of honey imported into Europe is actually a sugar water mix, with added flavourings and colouring.

A report by the British Beekeepers’ Association in 2022 summarised:

So where does that leave the consumer? Well, the oldest of sayings always hangs true. If the price looks too good to be true then it probably is. If you are happy to take that risk on your 75p jar of honey, or even that reassuringly expensive jar of supermarket honey, first take a look at the back and see where it has come from and ask yourself how sure you are that it is what it claims to be.

So, what do you do?

Buying direct from a beekeeper is the best way to make sure you are getting what you are paying for, as any honey which has passed through a supermarket supply chain, particularly with overseas origins and sold cheaply, might not be quite what it claims to be.

Much has been written about the claimed benefits of raw local honey to help reduce the symptoms of hayfever. Little of it has scientific backing, perhaps because there is nothing to be gained, financially speaking, by the larger pharma companies from doing the work.

This leaves the anecdotal words of those who have suffered from hayfever and found local honey to be beneficial in reducing the affects, whether directly or indirectly. The principle is a simple one. Eat raw, unprocessed honey, which still contains pollen, and in consuming that pollen it finds its way into your mouth/nasal passages etc and helps desentisize you.

My own personal experience was that of a 20 something having steroid injections once a month through the summer just so that I could survive. After a season of taking regular unprocessed honey (teaspoon a day) I found my symptoms reduced to the level where only on the highest of pollen level days did I need an antihistamine tablet. This was a direct trigger to me starting to keep my own bees. Now the only pollen that affects me is when the grasses are in full flow, as bees don’t collect grass pollen, it is wind distributed.

So, if you want to give it a go what should you, or shouldn’t you, do?

Firstly you need untreated (not over-heated, not micro-filtered) raw honey. Overheating breaks the sugar strings and damages the more subtle enzymes and structure of the honey. Micro-filtering removes all particles, including the beneficial pollen. Both of these processes make liquid honey stay liquid for longer, ideal for bulk storage on supermarket shelves.

Whilst our use of ‘Raw’ to describe honey is unregulated, you get the idea and can decide how much processing you want in your honey.

Out of interest, last year we had our late season honey tested and there were 35 different types of pollen. When we jar our honey we mix early and late season, further increasing the range of flowers visited to produce the depth of flavour in the honey and for its pollen content. Ours includes:

This list surprised even us, our bees are truly busy when it comes to visiting a wide range of flowers and collecting nectar and pollen.

So, after ‘raw and unprocessed’, ‘local’ is a good principle to use when buying honey for hayfever. However, saying that, the important thing is to have honey from an area where the crops and wild flowers etc are similar to your area. Taking it to the extreme, if you live in Essex and suffer when the oil seed rape is in flower, then pretty much any honey from Essex, or areas with fields of yellow, is going to be the honey to go for, whereas Scottish Heather honey isn’t going to help you much (delicious as it is).

Hope that explanation helps answer some of the questions I always receive at this time of year about honey for hayfever.

OK, I have to admit to being a bit rubbish at this blogging at the moment. Life has been extremely busy, but the bees go on and have had a very busy year, doing their bit for pollination and generously providing some excess honey beyond what they need for their winter stores.

A hot dry summer is a double edged sword. Whilst the bees are out and about in the heat, it isn’t great for honey. The general lack of water and moisture in the soil reduces the amount of nectar produced in flowers and so reduces honey production by the bees. We must also be extra vigilant to provide a water source for the bees as it is essential for their survival.

It didn’t deter the swarming season though. Here’s one after collection from a local village, just about to be rehomed.

September is the end of the beekeeping season. Whilst there are a few flowers left and the bees still fly on warm days, it is the month we remove the last of the excess late season honey and tuck up the bees for their, and our, winter rest.

phew…

Well, it’s April and the bees are flying at every opportunity. Whilst pollen and nectar sources are not overly abundant, when the temperature is above 12 degrees or so the bees fly. They do bring back some early pollen, which is a sign of a laying queen, always good to see, and they can use the good weather for a bit of spring cleaning.

The oil seed rape is already coming into flower and within a few weeks will yield nectar and ultimately provide the first honey harvest of the year.

It’s Spring…

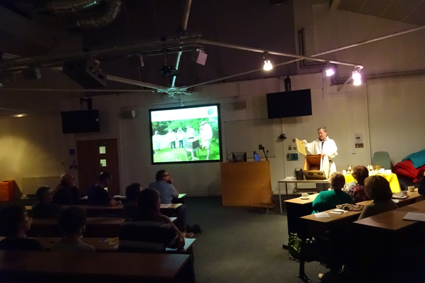

I have received quite a few enquiries regarding giving my talks via Zoom.

Having dipped my toe in the process over last summer, I have now given quite a number of Zoom talks to WIs, U3As and similar groups.

Given the continuing lockdown and likely extended restrictions, it seems that more groups are now setting up regular Zoom meetings and I am receiving more calls asking about the suitability of my talks for zoom. So I thought it useful to put up a post to let anyone interested know that my talks do work well for Zoom and that I am happy to help out.

It of course means that I am not restricted travel wise so can offer my talks to groups beyond Essex.

Full details of my talks are here.

The talks which work best for zoom are:

Feel free to contact me for further information.

I know it has been a while since I last posted, but circumstances have conspired against me.

Apart from WordPress introducing a baffling new layout which I find infuriating and leaving me not wanting to fight my way through it to post here, it doesn’t mean I haven’t been busy, especially in relation to the bees.

Below is an amazing picture, where the queen and bees have decided to lay some brood in precisely the shape of a hexagon, within a frame of stored food. This is the shape they use for each cell in their comb, as it is the most efficient use of space. To then use it on a larger scale for the brood pattern is one of those amazing things bees do.

At last it’s time to finish off my weather vane posts. I last left the story with the base of the weather vane in zinc undercoat. I finished off the pig for the ‘wind’ part from plasma cut aluminium and balanced it on a rod with a curly tail end for decoration and balance. This fitted over the vertical part of the main vane stem with a greased ball bearing to allow it to swing easily in the wind.

With the whole assembly screwed in place of the original tatty weather vane, I was quite pleased with the result.

Here is a close up of the pig:

I know I have been remiss in not posting the picture of the finished weather vane, but in the meantime, Happy Xmas to everyone. Be kind.

I am overdue part 2 of my weather vane project, so here goes.

This is of course the main body after zinc undercoating.

it weighs about 3 times as much as the ‘shop bought’ one it replaces and should last a lot more than 3 times as long. I have added some twists and scrolls to the design, partly for strength but mainly for decoration.

I have also added my trademark, and favourite, use of organic scrolls along with industrial rivets in the strapping design to support the vertical post. A quick bit of compass work also confirmed the need for a twist in the post to get it perfectly aligned.

Now to the N, E, S and W indicators and the all important vane itself.

I have been thinking for a while that I need to replace the shop bought weather vane, currently sitting over the garage, with a proper blacksmith made weather vane.

The current weather vane, as seen here, was bought about 20 years ago from a garden centre somewhere long forgotten.

The current weather vane, as seen here, was bought about 20 years ago from a garden centre somewhere long forgotten.

It was chosen more for its subject matter than its overall design, pigs being a favourite of my wife.

However, over recent years the weather has taken its toll and I have had to make a few running repairs to the arms. From a distance it still looks OK, but for a while I have wanted to make a slightly more ornate weather vane before the old one falls apart.

So now I have set the scene, the work began. The one stipulation was that it must have the same basic pig design. I therefore started by taking a photograph of the pig and blowing it up onto aluminium sheet, but more of that to come.

The final stage of making our 25th wedding anniversary celebration bench was to make the slats for the seating. These were made from oak, from another plank bought from the National Trust, Ickworth wood fair.

It took quite a bit of cutting and planing to produce the slats, but the results are very pleasing.

Below is a picture of the completed bench in the garden.

Following on from my last post, it was now time to start rebuilding the bench.

The first part I made was the back. I chose a lovely piece of oak, which I had in store for about 3 years since buying it at the Ickworth wood fair. It was felled from the estate, so has provenance, and I have the reassurance that it was part of an active RHS woodland management process.

The design is based on the script we made for our wedding party invitations, with added ribbons curling to the ends. Having cut the plank to the basic shape to fit the cast ends, I blew up the design, then stuck it to the wood before carving through it.

As an added touch I also decided to carve the back of this piece. Hardly anyone will ever see it, but that’s not the point.

I chose a sunflower design. It starts with a simple relief in a plate sized piece before carving out the detail:

For a while now I have been working on a special bench. A 25th wedding anniversary present to ourselves.

It all started with a chance purchase from one of our favourite junk shops in Hexham in November 2018. The owners were sitting outside the shop having a cup of tea. They were seated on a small Victorian cast end bench, which was for sale.

We had to buy it. 10 minutes later we were ‘feeding’ it into the car.

As we had assumed, all the woodwork was rotten, but the cast ends held much promise, and an opportunity for some wood carving.

Having borrowed some tools from the farm we stay at, the rotten wood was removed so that we could more easily load it into the car with all our other bits and pieces. My starting point was thus set, with an awful lot of work to do:

August brings the last honey extraction of the season and that means time for borage honey extracting. Borage is a beautiful blue flowered herb grown for its oil. It flowers over a very short period and, if you prepare well, and are lucky, your bees will bring it in as a single crop.

It doesn’t always work, but when it does, the honey is crystal clear and has a lovely delicate, light sweet taste, with a slight tang at the end. Its composition also means that it can take a year to set, compared to, for example, oil seed rape honey, which will set in a couple of weeks.

This year we had 100 acres of borage grown near to us, so we made sure we were ready for it. The first stage of honey extracting is to remove the wax capping over the honey, placed there by the bees to store it, and by default showing us that it is ‘ripe’.

The next stage is the extracting process itself. The frames are put into an extractor like the spokes in a wheel and spun. The honey simply flies out from the centrifugal force. No heat, no pressure, nothing unnatural.

The next stage is the extracting process itself. The frames are put into an extractor like the spokes in a wheel and spun. The honey simply flies out from the centrifugal force. No heat, no pressure, nothing unnatural.

The result from a little extra work is pure borage honey.

I jarred it up this morning and you can see the results below.

I have held up the jar of borage honey (on the left) against a jar our our regular mixed season honey, so that you can see just how clear it is.

We were lucky, in that 3 of the 13 supers we extracted were pure borage.

Last year we had none, next year who knows, but I love the ‘chase’ to get the purest of single crop honey. The fact that it is also my favourite tasting honey of all is a bonus. Get it while it lasts.

We have always solved the problem of differences in flowering times by planting in pots, which can then be moved around to maximise displays.

We have always solved the problem of differences in flowering times by planting in pots, which can then be moved around to maximise displays.

However, we now have a more permanent, and artificial, solution.

With electricity by the bucketful being generated by our solar panels, we are making as much use as possible, rather than just feeding it back to the grid.

The latest solution to both the lack of colourful flowers and the need to use excess electricity, has been a lot of experimentation in making fused glass ‘flowers’ in our kiln.

To the left you can see a selection of our, slightly over the top, glass ‘flowers’ in the sleeper garden.

Below are some closer pictures. They certainly don’t resemble any real flower, but that isn’t the point. They are just intended as a bit of fun and an interesting way of adding colour.

it was some time ago that I completed my carved elephant. It was always designed to stand on a glass platform, but the cost of running the glass kiln for a casting run has put me off.

That all changed when we had 25 solar panels installed late last year. They are currently generating around 20kW a day and so a 5 day kiln run using about 35kW doesn’t seem so bad.

I used the lost wax principle. This entailed first carving the base in wax. It was then used to create a mould from plaster and silica, reinforced with wire mesh. The mould is then inverted in the Aga to melt the wax out, leaving a plaster mould ready for the glass.

The glass comes in chunks and is simply placed in the mould at the start of the 5 day cycle, most of which is a very gradual cooling down annealing process to ensure the finished base doesn’t crack.

A few finishing touches and the elephant was glued to the base and stands proud as it was always designed to do:

Well, after a few tantalising glimpses of the different stages and parts of Bertie 2, here he is in his natural habitat.

I finished him with beeswax polish on his shell and a matt wood protection on his legs and head. This has given a nice contrasting sheen and matt finish.

As a homage to the original Bertie, here he is having recently woken up for another year.

Wooden Bertie now sits on the mantlepiece. At least I don’t have the worry and responsibility my sister has of looking after the real one.

All I need do is add a bit of polish once a year and not think about lettuce and, always his favourite, cucumber slices.

Time for the final part of my Bertie 2 project.

The interesting thing about carving a subject is just how much you study it first. Having had a tortoise in the family for 50 plus years and having him (or her, we still don’t really know) throughout my childhood, only now have I studied the differences between Bertie’s front and rear legs. As you can see from the pictures below, his rear legs are elephant like stumps, whereas his front legs are more flipper like.

The complication for his front legs is that, as a tortoise walks, the flippers bend inwards so his toes point towards each other, easier to see than explain, but it does make carving them quite challenging to get the movement and curves realistic.

Let’s start with the real life versions.

Then as translated into the carved versions for Bertie 2.

Next will come the final version revealed.

Part 3 of my project to make my own wooden tortoise was to carve Bertie’s head and face.

Part 3 of my project to make my own wooden tortoise was to carve Bertie’s head and face.

If it isn’t obvious, this is the real Bertie, my model.

The stages in carving wooden Bertie’s head are shown below. I was careful to select the angle of grain to give me the best chance of getting the lace grain across his head and shell.

To say it worked a treat is an understatement.

As you can see, the grain flowed down his head to help create the scaly look of his skin.

The second picture shows the outline head shape, with the eye marked on in pencil to make sure that I left enough wood to create the eyeball and lids.

In the third picture you can see the nostrils and form around the eyes roughed out.

I have also left a roll of skin on his neck to give him room to extend his neck.

The picture below shows his finished head:

Next time I will move on to his legs and claws.

It’s time for stage 2 of the project to carve my own Bertie. This comes with the news that the real Bertie has just woken up and lives for another year.

Having completed the outline shape of his shell, which revealed the beautiful lace grain of the London Plane wood, the next part of the project was to carve the ‘scales’ in the shell.

Having completed the outline shape of his shell, which revealed the beautiful lace grain of the London Plane wood, the next part of the project was to carve the ‘scales’ in the shell.

Normally this would be a freehand process allowing artistic interpretation. However, what I am doing is copying a real tortoise, so I had to start by studying all the photographs and copying out all the small nicks and curves from ‘real Bertie’ onto ‘wooden Bertie’.

This was then carved out using a simple ‘v’ chisel. As you can see from the first picture, whilst this gives the design, it is hardly realistic. The second picture is about 20 hours work later, where I have added depth to the scales both on their edges and through the undulations over their surfaces. The final picture has the additional texture from the layering in the scales.

This was then carved out using a simple ‘v’ chisel. As you can see from the first picture, whilst this gives the design, it is hardly realistic. The second picture is about 20 hours work later, where I have added depth to the scales both on their edges and through the undulations over their surfaces. The final picture has the additional texture from the layering in the scales.

All in all about 30 hours work and that doesn’t include the underside.

Come back soon for part 3, for Bertie’s head and face.

My latest woodworking project has been the creation of Bertie 2.

I need to explain. Bertie is ‘my’ first pet. Not many people of 50 something can say that their childhood pet is still alive, but mine is. Bertie was/is the family tortoise. He is at least 60 years old. He now lives with my sister.

As we don’t have the real Bertie, I decided that I would make my own wooden version.

As we don’t have the real Bertie, I decided that I would make my own wooden version.

As usual I will go through some of the stages in order to get to the finished piece.

Above is the real Bertie. He is about 20cm long, so a small tortoise.

My Bertie began with the choice of wood.

I decided to use London Plane, otherwise known as Lace wood.

It has a lovely grain. I cut it across the heart wood so that the lace look would come out across the shell.

Part 1 was the taking of a number pf pictures by my nephew, with Bertie placed on graph paper so that I could take key measurements.

Stage 1 of the carving process is below. Having selected the orientation to bring out the grain, I gradually formed the outline shape using my new home made carving stand based on a towing ball.

The final stage of the poppy is of course the instantly recognisable seed head.

The final stage of the poppy is of course the instantly recognisable seed head.

I made 2 for the sculpture.

I don’t have any pictures part way through, but they are made from 2 inch tube.

This is pinched top and bottom to create the stem and neck. The top is then flared out and shaped to create the feathered edge and the base pinched in to blend in with the stem.

There was then a rather long process of setting up the sculpture ready for my mum’s 80th birthday party.

There was then a rather long process of setting up the sculpture ready for my mum’s 80th birthday party.

There were many elements to arrange, with viewing points from the garden and the house windows. They then all needed setting into the stone.

An hour or so later and all was finished.

Following on from the first 2 stages of my poppy sculpture, it was time for the most difficult part, making the fully open poppy flower head.

You wouldn’t believe how many different types of poppy exist. I needed to set on a style, so I decided to go for the classic 4 petal design. I added furred edges to bring in my own design style and because I thought they needed a softer edge than the straight steel provided.

Work began with some real poppies, taking them apart, flattening out the petals and then making paper templates. I then used these to mark out the shapes of the 4 petals (which are actually different sizes) and then again my trusty new plasma cutter came into its own.

Shaping the petals into a natural look was quite difficult. Poppy petals are very thin and don’t hold their shape well, so a natural look is actually folded back and loose looking. I also hammered folds into the petals radiating outwards to give that paper look. Finally I added centres, again cut out with my plasma cutter and ridged to show the beginnings of the seed pod to come. Stems were added and the poppies finished.

For some reason I don’t seem to have taken any pictures of the process, only of the finished flower head, which is below. I made 2 to balance the sculpture.

Following on from stage 1 of my poppy sculpture project, the second stage of making the poppy sculpture was making the most important part, the poppy flowers.

I started by taking lots and lots of photographs through the summer months. The first thing that became very obvious was the amazing range of poppies to chose from. In the end I took a slightly artistic view of the classic 4 petal red poppy.

I then decided to show the flowers in 3 key stages, the developing bud, the fully open flower and finally the classic seed head.

Dealing with these in order, we of course start with the bud. This was made by first welding a piece of bar onto a smaller bar, the bud and the stem.

Dealing with these in order, we of course start with the bud. This was made by first welding a piece of bar onto a smaller bar, the bud and the stem.

Next I forged the shape of the bud, including a fold in the side to represent the unwrapping bud.

Next I forged the shape of the bud, including a fold in the side to represent the unwrapping bud.

Finally the stem was hammered and rounded to make it look less like a piece of bent rod. 3 of these were needed, at differing heights, for the final sculpture.

Finally the stem was hammered and rounded to make it look less like a piece of bent rod. 3 of these were needed, at differing heights, for the final sculpture.

That was about it, first stage of the flowers complete

I have been delaying revisiting my blacksmith poppies and the ‘how I made them’ bit. But here goes.

I have been delaying revisiting my blacksmith poppies and the ‘how I made them’ bit. But here goes.

First of all a reminder on the left of how it all finished up.

The rock was made from a piece we obtained from our favourite farm in Northumberland.

That was the easy bit, simply drilling some holes ready for the metal stems. Except it wasn’t that easy, think flower arranging with very heavy flowers and you get the idea.

On to the first element, the leaves.

First stage was to cut them out of 1.5mm sheet steel using my nice new plasma cutter.

As ever, the right tool for the job made it very easy to do, but without it, it would have been impossible.

The next stage was to form the sheet into leaf shapes. This required the forge and a heavy gauge V block.

The next stage was to form the sheet into leaf shapes. This required the forge and a heavy gauge V block.

A great deal of hammering and bending later and the sheet metal was looking much

more 3 dimensional and leaf like.

Repeated another 6 times and I had the 7 leaves I needed.

Repeated another 6 times and I had the 7 leaves I needed.

As with gardening, even numbers just doesn’t look right. There is probably a mathematical rule for it somewhere, but simply put, 7, not 6 and not 8, leaves were now ready for the next stage.

Come back soon for stage 2.

The cold of winter, and general lack of food for our feathered friends, makes it a great time to put up a blacksmith bird feeder.

The cold of winter, and general lack of food for our feathered friends, makes it a great time to put up a blacksmith bird feeder.

I have made 2 on a similar theme, basically because a lady asked me to make one against a sketch and then my wife liked it so much she wanted one too.

They are free standing, with a spike to push into the ground, 7 foot tall and made from 19mm steel. This makes them very substantial, able to stand up to the biggest birds and strongest winds, and to my general style of nothing thin and flimsy.

They were left in untreated steel finish, so will rust and age gracefully.

I just wanted to wish everyone a very Merry Christmas and a Happy New Year.

Continuing our love of making use of treasured things rather than buying new, this is a knitted wreath made by my Grandmother over 20 years ago. It comes out every year and has pride of place in our home.

If you are looking for the ideal Christmas present for that difficult to buy for person, blacksmith or beekeeping experience days might be just what you are looking for. I can supply you with a pdf gift card to print and give to the lucky person, with the date for the ‘day’ to be set later.

Full details of my experience days this year can be found on this link.

Whether you are interested in finding out more about beekeeping or blacksmithing, I can tailor make a day for you.

In a day designed around what you want to achieve and learn, a beekeeping experience day will involve opening up hives and gaining an understanding of how the hive lives and thrives.

Meanwhile, on a blacksmithing experience day, I first work with you before the day to understand what you would like to make on my outdoor forge.

I then work on your idea to make it something you can make, with a little help from me when needed. Alternatively, you can make a hanging basket bracket incorporating a number of blacksmithing techniques, to learn more about the art.

On the day itself you will learn key forge techniques and make something to take away and treasure.

“Thank you for such an amazing day!”

“We both had a great day and my wife is very impressed that we managed to produce such beautiful work – all of which was thanks to your excellent coaching. You made great use of our time and I’m still amazed that we managed to do quite so much in a few short hours.” – Patrick

“Thanks so much for sharing your knowledge and patience with us.” – Karen and Graham

“Wow what an amazing candle holder Dan made..I was gobsmacked….I absolutely loved it…thank you, Dan had an amazing time and hasn’t stopped talking about it….” – Leonie

“Thanks so much for making Henry’s day so enjoyable yesterday. He had a truly fabulous time and loved every minute of it. I am amazed and delighted at the sculpture he made in the time he had – his DT teacher was equally impressed. I think we have started something here! If you ever hear of any trainee opportunities, please let us know. He was still smiling at 3.30am when I woke him to go on his school trip to France.” – Rachel

Visit my students page to see some of the items they made.

Last year I was given a bucket of horseshoes to make into a sculpture.

Whilst the sculpture is still in the planning phase, I have made some heavy duty hooks for the kind person who gave me the shoes for their horse blankets. They should take the full weight of a couple of horse blankets each.

If you are looking for the ideal Christmas present, blacksmith or beekeeping experience days might be just what you are looking for. I can supply you with a pdf gift card to print and give to the lucky person, with the date for the ‘day’ to be set later.

Full details of my experience days this year can be found on this link.

Whether you are interested in finding out more about beekeeping or blacksmithing, I can tailor make a day for you.

In a day designed around what you want to achieve and learn, a beekeeping experience day will involve opening up hives and gaining an understanding of how the hive lives and thrives.

Meanwhile, on a blacksmithing experience day, I first work with you before the day to understand what you would like to make on my outdoor forge.

I then work on your idea to make it something you can make, with a little help from me when needed. Alternatively, you can make a hanging basket bracket incorporating a number of blacksmithing techniques, to learn more about the art.

On the day itself you will learn key forge techniques and make something to take away and treasure.

“Thank you for such an amazing day!”

“We both had a great day and my wife is very impressed that we managed to produce such beautiful work – all of which was thanks to your excellent coaching. You made great use of our time and I’m still amazed that we managed to do quite so much in a few short hours.” – Patrick

“Thanks so much for sharing your knowledge and patience with us.” – Karen and Graham

“Wow what an amazing candle holder Dan made..I was gobsmacked….I absolutely loved it…thank you, Dan had an amazing time and hasn’t stopped talking about it….” – Leonie

“Thanks so much for making Henry’s day so enjoyable yesterday. He had a truly fabulous time and loved every minute of it. I am amazed and delighted at the sculpture he made in the time he had – his DT teacher was equally impressed. I think we have started something here! If you ever hear of any trainee opportunities, please let us know. He was still smiling at 3.30am when I woke him to go on his school trip to France.” – Rachel

Visit my students page to see some of the items they made.

This week saw my mum’s 80th birthday, and with it a gathering of friends and family.

At the recent Malvern Autumn show we met a wonderful poet, Erin Bolens.

At the recent Malvern Autumn show we met a wonderful poet, Erin Bolens.

She was there as a part of a Poetry Takeaway event, where you give the poet some interesting facts about a person and then return later in the day to collect the poem.

It was a wonderful poem, which I read out at the party as a part of the toast, as in the main picture above.

It was also the official unveiling day for the poppy sculpture.

I will do another post showing the process of making the sculpture over the last few months, but here it is in its finished form. We delivered and assembled it a day early to make sure it was all OK.

Following the earlier success, it was time to make another fused glass table top.

The above picture shows the final top, as fitted to a table I made on the forge a while back.

The above picture shows the final top, as fitted to a table I made on the forge a while back.

It uses a very large industrial gear as the top, with organic forged legs held in place with a leaf wrap.

The process to produce the table top is the same as that on the table top on my last post. It took 4 stages of firing to turn the basic cut glass into the final design, as shown in the pictures below.

This one was based on our favourite flower, the fuchsia. It never fails to amaze me how the colours come out, just as they do when firing the glaze on ceramics. The picture on the left shows the first stage with the cut glass on the white background. The picture on the right is the end product, 4 firings and about 5 days later.

I’ve been working on a fused glass table top. It was designed to replace a mosaic top on a table I made from an old tractor wheel. The mosaic had suffered from last winter’s cold snap, flaking off.

The design was inspired by the agapanthus flowers we see along the roadside and in gardens all over South Africa.

The pictures below show the 3 stages of fusing. Ultimately the glass is fused ‘upside down’ to give it a flat and slip free surface. This is the same process I used with my carved oak tray.

It’s official, NICE, The National Institute for Health and Care Excellence says take good local honey for coughs and colds, rather than antibiotics. Been saying it for years…

I don’t usually do consumer stuff here, but today I have 13 good reasons not to shop at B&Q again.

First good reason is that, on Saturday at 4pm I ordered some specialised wood cleaning product on ebay and, with a knock at the door, it arrived at 9:30am Sunday morning.

Now, that isn’t a good enough reason in itself. I try to support actual shops, they have a tough job to keep going and the only reason I used ebay this time was because this was a specialist product not available at the local DIY outlets.

But here come the 12 other reasons.

Yesterday at 5pm I visited our local B&Q to buy a few bits to help repair a lintel on our dormer window. I know their till service is dreadful and so prefer Wickes, but their product range is good and I was close by and so decided to give them a go. Having collected what I needed I headed to the 12 tills. Not a single person on a till, not one. My heart sank when I realised that the only option was self-checkout.

I approached, waved my product under the scanner to be met by a flashing light and a ‘contact assistant’ message. A young lady approached, “Oh I need to get it approved for over 21!” (I am over 50 and sadly the days when I looked under 21 are some time behind me). She was not able to do this herself due to her age so wandered off towards the refund desk. A lady looked over at me, and nodded. Phew, I was apparently over 21.

The young lady wandered back and clicked a pass key against the till, then she wandered away.

2 seconds later the till bleeped again. She came back. “Oh yes, I need to click that again,” so she attached her pass key again.

Me, “I guess you don’t remember the days when there were assistants actually serving customers in shops?” She didn’t get it.

I struggled on, reading through the menus presented to me; I finally pressed the ‘pay by credit card’ option.

I then realised that I hadn’t scanned my B&Q card. I looked for a button to scan it and tried a random scan, nothing.

I looked across for the ‘helper’ and she began to wander over (I am still the only person at any till, so she isn’t busy).

I began to explain that I needed to scan my B&Q card, but didn’t know how.

At that point I realised just how stupid this all was.

Me to ‘helper’, “Do you know what, if B&Q can’t be bothered to have a single till open and you can’t be bothered to serve me then why should I bother to try to be a customer. You can keep this and I will go somewhere that actually wants my business.”

I left my things at the till and walked away.

The one thing that shops have over online purchasing is the personal service. They used to have immediacy of availability. I remember only a few years ago when you ordered things by post or phone that delivery was always quoted as ‘within 28 days’, and it often was only just that. Now, it is a click and fewer than 28 hours away, generally cheaper and always with greater choice.

Shops seem to now be willingly pushing us away from any human contact. They are committing suicide with home-made swords. Each shop expecting us to become an expert with their unique computer scanning system in order to be allowed to buy anything. All the time avoiding eye contact should we actually want to ask anyone anything.

There are many reasons why the likes of Aldi are doing so well. One might just be that they actually have people on their tills, serving.

Perhaps B&Q will read this, perhaps not. I am sure they have lots of statistics presented to their senior management showing how much quicker self-service is for customers, and so how great it is. They used to do this for ‘offshoring’ call centres, before realising that the reality was that customers don’t like it and go elsewhere where they can. Now companies positively advertise ‘UK call centres’ as a feature of their business.

B&Q management might hide behind blaming the young assistant for ‘not providing the customer service they expect’, but that isn’t the point. The point is the senior management decision to put her in that place, too young to actually process many items, and to then leave the 12 perfectly good tills unattended. But they will never acknowledge that, it would be too close to home and too much of a question against the strategy they carefully crafted during a long away-day somewhere.

Give it a couple of years and those large shops still left might suddenly have a new modern approach to their last bastion, customer service. They might have people actually behind tills to serve you, with a smile and a cheery, helpful approach. You can always hope.

In the meantime, must go, I hear the doorbell. It’s the bits I needed for the lintel repair arriving from the ebay order I placed last night…

I can’t help but post pictures of more veggies.

I can’t help but post pictures of more veggies.

The courgettes really are taking over. The warm weather has turned them into wild things growing before our eyes.

This one has come from a plant alongside an old hanging basket container used to protect some lettuce from being eaten by our the escaping hens.

Unfortunately I missed it and it made its own attempt to break through, which of course failed.

Meanwhile the hot weather has brought on the peaches.

Meanwhile the hot weather has brought on the peaches.

This year they are the biggest we have ever grown.

Protected from the wasps by fleece, we are enjoying the sweetest, juiciest peaches ever.

The courgettes are taking over the garden.

The courgettes are taking over the garden.

We have grown more varieties than ever and the hot weather has brought them on amazingly. Suggestions for recipes gratefully received.

On other subjects, I am currently working on a special sculpture for my mum’s 80th. For obvious reasons no pictures until after the important day in October.

Yesterday was Mildred’s 85th birthday and she had a day out at the seaside.

Yesterday was Mildred’s 85th birthday and she had a day out at the seaside.

We headed off at 9am, balloons and birthday signs on show, and took the opportunity for a leg stretch beside a lovely field of echium.

If only we had the bees with us, as it makes lovely honey.

Next stop was Manningtree, where we almost saw the sea.

Next stop was Manningtree, where we almost saw the sea.

It was a brief stop as we were heading on to see Grayson Perry’s art house building in Wrabness.

Whilst the garden is lacking in any care, the house itself was very impressive, and only a couple of thousand to stay in for a short break in the summer (providing you win the ballot).

A quick break for the most delicious fish and chips and we were off to visit an old family friend at Frinton-on-Sea.

A quick break for the most delicious fish and chips and we were off to visit an old family friend at Frinton-on-Sea.

It had been too long since we last caught up on life and, at an amazingly sprightly 94 (she won’t mind me saying), she beat Mildred into this world by nearly a decade. Mildred took her for a short ride and they both had a lovely time.

11 hours and 130 miles later we arrived home to be greeted by our 92 year old neighbour, who was out gardening.

11 hours and 130 miles later we arrived home to be greeted by our 92 year old neighbour, who was out gardening.

The balloons were, by now, sagging somewhat and we had replaced a couple along the way.

There may be many things wrong with this world, but, with the average age of Mildred, our neighbour and family friend at over 90, we are all living longer than ever.

That’s the key, as the song goes, ‘Enjoy yourself, it’s later than you think‘.

At last Mildred has had her new front spring fitted.

Having fitted her new rear springs about 3 years ago, her front sprint has languished in the workshop. Finally I decided that I had delayed for too long and so volunteered her for a workshop day.

12 keen Austin 7 owners assembled for a 4 hour session, where her old saggy spring was replaced with a nice new firm spring.

In this first picture you can see the old worn spring behind the nice new one, wrapped in denso tape to protect it from road grime and grit.

The spring is held in place by two U bolt clamps in the middle and then by shackles at the ends, secured to the hubs.

Much fiddling was required to get to the nuts on the U bolts, as you can see from the assembled crowd leaning in, over and under Mildred.

However, fuelled by tea and cake, we succeeded. Mildred’s spring was safely secured. She now sits about an inch higher than before and with a firmer ride, so she no longer rubs her tyre on the inside of the front wing when braking and taking a sharp turn.

She also looks much happier with her new springs all round and gleaming shackles.

I was recently asked if I could make a Tower Bridge sculpture for a special birthday present. It was to hang on a wall, but have depth to it, and be 1m long. A lot of sketching and design work later and all was agreed. It was the perfect job to make use of my new plasma cutter to produce the towers and window cut outs.

The result is below. The finish is burnished steel, lacquered to protect the look.

I didn’t take many pictures along the way but the one below shows the base frame from which everything hangs. This gives it strength and makes sure everything is nice and square from the start.

For some time now we have had Gardeners’ World cloche envy.

I have some home made cloches made from some old bases used on an exhibition stand and then rescued from a skip about 10 years ago.

I have some home made cloches made from some old bases used on an exhibition stand and then rescued from a skip about 10 years ago.

They are (were), to say the least, ropey. They were rusty, the hoops were made from plastic pipe, which had deteriorated, and they were covered in torn netting.

With spring finally approaching and Monty Don’s cloches in full view on Gardeners’ World, the time had come to update ours.

I started by cleaning them back to rust free metal. Then I welded in 10mm steel hoops for stability. Finally some old corrugated sheeting, saved from a skip having served its purpose as a friend’s ‘lean-to’ roof, was cut to slot inside the hoops. The end panels were then made from some offcut plastic sheeting used in picture framing.

The plastic can then be slid out and replaced with netting for summer protection of brasicas.

A coat of rust protecting undercoat and black paint and we are no longer quite so envious.

Cost about £2 for the metal used in the hoops and £3 of paint, the rest recycled, result.

Only thing is, Monty has many more that we have, and I have just found another base behind the polytunnel ripe for conversion. So it’s back to work…

Today we spent a few hours saving some bees.

A bee friendly home owner was having a dying Ash tree removed and wanted to save the bee colony, which had made a cavity some 20 foot up its trunk, home.

The day involved 2 tree surgeons, 2 beekeepers, 2 home owners, 2 dogs and lots of tea. It all started with a cold morning, smoke, rags to block the holes in the trunk and some clingfilm to block all exits.

Next the 1/2 tonne trunk was cut off with a chainsaw and lowered to the ground.

Next the 1/2 tonne trunk was cut off with a chainsaw and lowered to the ground.

With the bees apparently unworried by the whole process, we decided it was time for a second cup of tea.

A couple of very careful cuts later and we had access to the colony.

A couple of very careful cuts later and we had access to the colony.

We had initially thought the colony had made its home down the centre of the dying trunk, but it became clear that they had made their home in a medicine ball sized cavity, which looked like it had been a woodpecker nest.

Finally came the easiest part.

The pieces of comb came away quite easily, all well filled with brood, larvae and eggs.

The last of the bees were brushed carefully into the hive and we were done.

An hour later and the hive was installed in our apiary to settle down after the excitement of the day.

Whilst the weather, cold and drizzly, was perfect for moving bees, we were quite amazed just how docile they were. Having been subjected to the noise and vibration of a chainsaw, swung from a rope at 20 foot up, and then pulled around, they barely needed the smoke, they just sat there good as gold and let us move them around.

3 hours after we started, the job was done and the rain came down.

At last I have finished and installed my blacksmith gate.

I wanted to give it some strength and bulk in the posts, so have used 20cm by 10cm oak sleepers.

It has taken me a while to get it all finished, and of course the weather hasn’t helped, but here it is.

The last stage for the gate was to add vertically standing leaves to the base. These partly block out gaps, but are mainly decorative, giving the gate structure and weight both literally and figuratively.

Having finished the gate I decided to get it galvanised. This is a process where the metal is zinc coated to protect from rust. Any scratches are covered by zinc oxide before any iron oxide can form.

There is a great galvanisers near to us which I use.

There is a great galvanisers near to us which I use.

They have a minimum weight, so I took the opportunity to have a table I made in the summer from an old gear wheel galvanised at the same time.

On the left is the pile of bits ready on the pallet and then the finished galvanised gate. The shiny finish is the zinc. Left alone it would be perfectly protected, but would dull down to a boring grey, just like corrugated iron roofing.

This is how it has finished with its silk black painted finish. I will put up more pictures when it is installed, showing the hinges and arch over the gate.

Right, with the design sorted out it was time to start the fun, the making bit.

I started by setting out the frame.

I started by setting out the frame.

As with most of my work, I began with organic curves, rather than lots of straight lines.

It is important to balance design with structural integrity. Stating the obvious, whilst it must look good, it must also support its own weight, hang on the hinges without stress breaks, and of course keep out those we want to keep out.

The curved piece at the base does exactly that, it braces the bottom, curles up to support the bottom hinge point and then finishes off in a purely decorative leaf design.

This is the next stage in the design. I have added a top hinge, vertical pieces to add bracing and design, and a top curved piece to replicate the one at the bottom.

This is the next stage in the design. I have added a top hinge, vertical pieces to add bracing and design, and a top curved piece to replicate the one at the bottom.

I am liking how it is coming along, the balance feels right.

It’s time to make another gate.

We need a new gate to get to the other side of our hedge to make cutting it easier. I drew up a rough idea and have been slowly making it over the last few months in a snatched hour here and there as time has allowed.

So, here we go with part 1, this is my ‘highly detailed’ sketch. The only really important details are the overall dimensions so that it fits a standard width gate, the rest can evolve to ensure that it looks balanced.

Over the last few months I have been making an oak carved tray with glass insert. It was made from a solid piece of oak, carved with rope edging and straps. To say I am now ‘roped out’ is an understatement. The textures elements to the twisted strands took a long time but they do add a lot of movement to the piece and help make it look more realistic.

You can see my template piece of rope in the earlier pictures below, which helped me work out how the twists moved as they went around the corners. They don’t move how you might think, as the twists tighten on the inside and open up on the outside, so you just need to go with the measurements, and know that it will look right. This is how it finished up:

I have written about the tray in the past, but here is a series of pictures showing how it developed from a plank, through a simple solid cylinder around the tray, on to the carving of the rope shape. I had 3 attempts at getting the curve right around the corners, using my piece of rope and a plastic template with the curls marked out on it. Remembering to leave enough wood to make the straps:

The glass insert was made a few months ago. I used real ferns, with glass powder, to produce the fern design on white background. It takes 3 firings to make the glass insert. I wrote about it at the time.

Unfortunately Mildred has been a little off colour. She ventured out on New Year’s Day with her friends for our traditional New Year opener.

All began well.

All began well.

We arrived at the local Church to join the queue of 30 Austin Sevens, and a few assorted others, to enjoy mince pies and (non-alcoholic) mulled wine.

We then happily set off on our 25 mile run.

Unfortunately we didn’t get to the end. About half way through we spluttered to a halt. It looked as if the head gasket had failed, nothing that could be solved at the roadside.

With thanks to our insurers and SOS road rescue, we had a truck with us within the hour and were on our way home.

For anyone technically minded, this is what I found when I removed the head, a missing piece of gasket, which appears to have broken away.

For anyone technically minded, this is what I found when I removed the head, a missing piece of gasket, which appears to have broken away.

The result is loss of compression in cylinders 2 and 3.

Mildred is now well on the way to recovery. The new gasket is bedding in and she should be back on the road in a day or 2.

Wishing everyone a Merry Christmas and a Happy, Healthy and enjoyable 2018.

After my earlier post about blacksmith experience days as gifts for Christmas, A couple of people have asked me about the pieces people have made.

First is the hanging basket bracket.

First is the hanging basket bracket.

These two were made by Patrick and his daughter Charlotte.

I use this design to help people who want to learn a number of techniques, but don’t have a specific item they want to make.

The important thing to remember is that the day is yours. If you have something specific you would like to make then, before the day, I will help to develop your idea into something you can make in a day on the forge.

Some of the other things made include:

If you are looking for the ideal Christmas present, blacksmithing or beekeeping experience days might be just what you are looking for. I can supply you with a pdf gift card to print and give to the lucky person, with the date for the ‘day’ to be set later.

I have held a few experience days over the year and wanted to share a few pictures.

Whether you are interested in finding out more about beekeeping or blacksmithing, I can tailor make a day for you.

In a day designed around what you want to achieve and learn, a beekeeping experience day will involve opening up hives and gaining an understanding of how the hive lives and thrives.

Meanwhile, on a blacksmithing experience day, I first work with you before the day to understand what you would like to make on my outdoor forge.

I then work on your idea to make it something you can make, with a little help from me when needed. Alternatively, you can make a hanging basket bracket incorporating a number of blacksmithing techniques, to learn more about the art.

On the day itself you will learn key forge techniques and make something to take away and treasure.

“Thank you for such an amazing day!”

“We both had a great day and my wife is very impressed that we managed to produce such beautiful work – all of which was thanks to your excellent coaching. You made great use of our time and I’m still amazed that we managed to do quite so much in a few short hours.” – Patrick

“Thanks so much for sharing your knowledge and patience with us.” – Karen and Graham

“Wow what an amazing candle holder Dan made..I was gobsmacked….I absolutely loved it…thank you, Dan had an amazing time and hasn’t stopped talking about it….” – Leonie

“Thanks so much for making Henry’s day so enjoyable yesterday. He had a truly fabulous time and loved every minute of it. I am amazed and delighted at the sculpture he made in the time he had – his DT teacher was equally impressed. I think we have started something here! If you ever hear of any trainee opportunities, please let us know. He was still smiling at 3.30am when I woke him to go on his school trip to France.” – Rachel

Please contact me if you have any questions about my experience days, or if I can help create the perfect christmas or birthday present.

It has been a busy weekend. Over the last few months I have been working, on and off, on an oak tray. It will eventually take the glass fern sheet I previously blogged about.

This is where I was up to before the weekend began.

This is where I was up to before the weekend began.

The rope edging was prepared as a cylindrical shape and I had a piece of nylon rope to copy.

The oak is hard and difficult to carve, but it should give a wonderful deep colour and grain.

The picture below shows the tray after about 22 hours of carving. The most difficult bit is getting the strands in the right place as they move around a bend. The piece of rope was invaluable in seeing what actually happens to the strands as the rope bends and moves.

The section at the top of the tray is closest to being finished and that to the right little more than the initial outline marked.

There is still much to do.

Life has been a little busy over the last few weeks. The vegetables and fruit have been growing faster than we can eat, freeze, store or make jam from.

We are particularly pleased with the tomatoes. Having lost all of our 30 plus plants to tomato blight last year, this year we spent some time researching blight resistant varieties.

We picked 10 of the best and haven’t had a problem with any. We have grown them in a variety of places from a polytunnel to a greenhouse and out in the open.

Remembering just how much rain we have suffered this summer, it is amazing that they have shown not a single sign of blight. The results speak for themselves…N0w must go, I have a couple of buckets of runner beans in need of picking.

Having tried out a few different techniques for glass fusing with ferns, and finalising the best, I have now moved on to the main reason for all this, the insert for the oak tray I am currently carving.

I started with 3 ferns coated with green glass powder.

I started with 3 ferns coated with green glass powder.

These were fused to a sheet of clear glass.

With the carbon residue from the ferns themselves removed, this left the glass powder behind, reflecting the fern shape and form.

Next the sheet was turned upside down and a sheet of opaque white glass put on top, as the background.

This meant that what was to become the top surface was against the kiln plate. The reason I did it this was around was to give the top surface a textured finish to match the fern feel. The glossy, shiny top surface of the glass in then on the bottom and hidden.

The result is below:

I have tried to show the silk surface texture in this picture.

I have tried to show the silk surface texture in this picture.

All I need to do now is complete the oak tray which this will be inserted into.

We had mixed results from the glass fusing with ferns.

Good news is that two of the techniques worked really well, the other 7 didn’t.

Without going into too much detail, unsuprisingly ferns by themselves turn to ash at glass melting temperatures. This can be used to create interesting fossil type effects as on 3 above, but at the risk of also creating large bubbles if you don’t use slow temperature ramps. If the fern is delicate then, as on sample 2 above, it is likely to completely disappear.

The key appears to be use glass powder stuck to the fern, as on 1 and 8 above, with a 2 stage process to reduce bubbles, as on 8.

8 is therefore my method of choice to produce a fern in glass. Using this methodology, next comes the large piece I need for the oak carved tray I am making. I just have to hope that the method scales up.

Even since we saw some glass fusing with plant material I have wanted to have a go.

Time, the garden, and the bees have conspired to thwart our attempts to find the couple of hours needed to try it out, but, with the nasty weather over the last few days, we decided that today was the day.

A little online research brought up about 4 different techniques to cope with the basic problem that, at 800 degrees, the temperature required to melt the glass, all plant material will have turned to carbon.

This picture shows the 9 different test pieces, all slightly different, to determine the process that works best for us for different leaf types.

Come back in a couple of days to see the results.

In the meantime keep your fingers crossed.

It has been a while since I last posted. The garden is in full swing and harvesting the soft fruit (blackberries, blueberries, redcurrants, blackcurrants, gooseberries) has been my priority. it has truly been a bounty this year ad we haven’t even started on the apples and plums.

Squashes and courgettes are also getting underway and the garlic needs digging up, so you get my point, food comes first.

Having said that, the bees have also been busy. We have completed the first extraction of the year and the bees in the long hive are doing well.

Here is one of the long hive frames, as seen during a recent beekeeping experience day. They are pulling out the comb to fit the V shaped hive and have built up 6 frames already. I’ll try to post some more detailed pictures soon, but that’s it for now.

I recently held a blacksmith experience day for my youngest ever pupil.

I recently held a blacksmith experience day for my youngest ever pupil.

It was a part of his school work experience programme.

He made a sculpture incorporating a number of core blacksmithing techniques, and a special addition of his own, a worm.

It was a first for me, a forged worm. I think we were both pleased with how it all came out.

His Design Technology teacher was reportedly also impressed with his work for the day.

Alongside the forge work, he also took the opportunity to ask lots of questions about becoming a blacksmith and took away lots of information about courses and qualifications.

He was a pleasure to teach.

Following on from my earlier post about the making of our long hive, it now has inhabitants.

Following on from my earlier post about the making of our long hive, it now has inhabitants.

I collected a swarm the other day. It was a fairly simple collection, hanging at head height in a tree. I knocked them into my skep and then waited whilst the stragglers and scout bees made their way back to the colony.

There will always be a few left behind, but, providing you are prepared to be patient and you have the queen in the skep, the others will follow.

Here you can see them in the skep and then after being knocked into the hive.

They quickly took to their new home and within a few hours had begun to draw out the small bits of wax foundation into comb.

With any luck they will have time this year to pull the comb out sufficiently to give them space to put honey for their winter store. This will set them up for a strong 2018, when we might get some cut comb honey from them.

I was recently asked to help a friend out with a frame to both hold a compost bag and to give a frame to lean on whilst digging into the bag.

I was recently asked to help a friend out with a frame to both hold a compost bag and to give a frame to lean on whilst digging into the bag.

The result is here.

Nothing too complicated, a large diameter ring for the base, 3 vertical rods and a smaller diameter ring at the top. This gives it extra stability.

It’s the second one I have made, this one from 12mm steel to give it extra strength when leant on.

Further to the Nunti I made, I was also asked to make another Nunti Bo, this time for Juan in Spain.

Further to the Nunti I made, I was also asked to make another Nunti Bo, this time for Juan in Spain.

I made one a few months ago for Garry.

It is made from a Japanese Redwood Bo (shaft) with a forged steel end, finished simply with beeswax polish from our own bees.

This is apparently based on a fisherman’s spear and now used in Okinawan martial arts.

I am no martial arts expert, but I understand that it is composed of a Bo (the wooden shaft) with a Manji Sai mounted on one end.

Following on from the Nunti Bo I made a few months ago, I was asked to make 2 handheld Nunti. I think they are also sometimes referred to as Sai.

Following on from the Nunti Bo I made a few months ago, I was asked to make 2 handheld Nunti. I think they are also sometimes referred to as Sai.

These are used in the Japanese martial art discipline from Okinawa.

I really enjoyed making these. I worked with Garry to work put the size and weight to give them a good balance. They have a lovely feel and weight and I am very pleased with how they have come out.

You can see the stages of manufacture below.

They are finished with simple beeswax polish from our own bees.

Perhaps one of the oldest methods of keeping bees is top bar Long Hive Beekeeping. Popular in Africa, largely due to the low cost of hive manufacture, it is now becoming popular in Europe as a bee and environmentally friendly method of beekeeping.

A few weeks ago Mrs Bee found some online plans and so I set to work. A trip to B&Q later and I had a sheet of plywood ready to make into a hive. Leaping forward, this is how it finished up.

And this is how I got there:

This shows the inside of the hive.

This shows the inside of the hive.

The frames are very different to those in a conventional hive, in that they are simple top bars.

A small piece of wax sheet is added to give the bees a subtle hint as to where we would like them to build comb.

And that’s about it. All I need now are some bees, oh and some warm weather..

It’s that time again. Time to mark the second anniversary of leaving e2v.

I marked the anniversary of my last day last year. This time I have slipped by a few days. it doesn’t seem quite so important this year.

Much has happened since I left. e2v has recently been sold to an American company and is now Teledyne e2v. Whilst there have been immediate cuts in management (the CEO and my old boss have left), Teledyne has a history of investment in aquisitions. So I have hopes that e2v will go forward and thrive, with new backing and access to US markets.

From my perspective, I am doing more talks, with new social history talks added, and am enjoying expanding my blacksmithing and beekeeping activities.

This year I marked the anniversary by visiting Harwich. Mrs Bee was on a painting day, so I acted as driver and took the opportunity to visit some old haunts (literally).

Mot of the interesting museums around Harwich were closed, but what I really wanted to do was go and see the pier at Walton on the Naze. To be honest their web site sort of lines you up for the place, a little tired in places, but honest and clearly providing loads of fun for the visitors I saw.

In my formative years I attended Moulsham Church Sunday School. My memories are not of excessive religious teachings, but of fun and games. So that’s a big tick in the box for them.

One of my overriding memories is of the annual summer trip to Walton on the Naze, which included a visit to the pier and jelly and ice cream on the way home. The highlight for me was the ghost train, especially the bits where the train crashed through doors, swung out into the open air and then back through more doors into the dark, all at about 50 foot in the air and 50 miles an hour.

I wandered down the pier with some trepidation. Never go back they say, it will only ever lead to disappointment. Memories came back as I walked down the centre of the pier. It really hadn’t changed much. The first areas to the left and right were full of slot and games machines, much updated from the one armed bandits of 40 years ago.

I wandered down the pier with some trepidation. Never go back they say, it will only ever lead to disappointment. Memories came back as I walked down the centre of the pier. It really hadn’t changed much. The first areas to the left and right were full of slot and games machines, much updated from the one armed bandits of 40 years ago.

Then, there it was, the ghost train.

I couldn’t believe it was still there. It has changed of course. The bits where you swung out into the open were boxed in as windows, probably Health and Safety said that it was too dangerous. But the doors were still there, enclosed, it was still basically the same ride.

I couldn’t believe it was still there. It has changed of course. The bits where you swung out into the open were boxed in as windows, probably Health and Safety said that it was too dangerous. But the doors were still there, enclosed, it was still basically the same ride.

But. horror of horrors. It was 11:30 and it was closed. with my parking ticket running out at 12:20 (never had that problem as a 10 year old), it opened at 12, just enough time I calculated. I checked that I was allowed to ride and, after a visual assessment of my weight, I was given the nod. 3 tickets, or £1:80 later, I was on board.

It was great, not as fast as I remember and the boxed in bits that swung out in the open had been lowered from 50 foot up to a modest 6 foot (or just possibly they had always been only 6 foot up, but I don’t think so).

It was great, not as fast as I remember and the boxed in bits that swung out in the open had been lowered from 50 foot up to a modest 6 foot (or just possibly they had always been only 6 foot up, but I don’t think so).

But it was great. It was the ghost train of 40 years ago. I did video the ride, but am having trouble loading it. You can see a better attempt here.

I was 10 for about 3 minutes, then I had to get back to the car park before I got a ticket.

Here is the finished carved wooden chain.

Here is the finished carved wooden chain.

It didn’t take much more work to clean off the links.

The biggest job as always was the sanding, working through 80 grit, down to 320, to achieve a really smooth finish.

You can’t see it very well here, but there is some interesting spalting in the beech, which runs through the first links, giving it a mottled effect.

The finish is our own beeswax polish.

My next project is a tray to take some tiles we bought in South Africa. But for now the garden calls. There are seeds to plant and a new hedge to lay.

We resume work on my wooden chain with the difficult process of freeing up the individual elements.

In the first picture above you can see the hook end with most of the material removed. All that is left is the tricky bit, removing the wood in the tight gap joining the hook to the next link. The first part to remove is here in the second picture, and easy to get at. The third picture shows the result of another hour’s work, nibbling away at the wood between links and freeing them up. For the first time we have completely separate pieces of wood, linked together.

It now becomes a somewhat repetitive task, working along the links, freeing them from each other. At this point they are far from finished. A lot of work still needs to be done to even up the chain shapes.

This is the point where I leave it for now. All the links are free, but in need of a few more days work to finish them off. Time I don’t have right now as I have work to do to prepare for a blacksmith experience day this weekend.

This is the point where I leave it for now. All the links are free, but in need of a few more days work to finish them off. Time I don’t have right now as I have work to do to prepare for a blacksmith experience day this weekend.

I can also explain the first question posed, about making a single piece of wood longer than you started. The links as drawn on the original piece needed gaps between them to allow a chisel in. By the time the links are thinned out and finished off they will stretch out further and so the chain will still be make from a single piece, but will be longer than the original block it is made from.

How do you make a piece of wood longer? It is a question I was asked the other day, and the answer is simple, you make it into a carved wooden chain. Stick with me and you will see how.

It is an exercise I haven’t tried before and so I began it during a wood carving weekend with the help of a very good teacher.