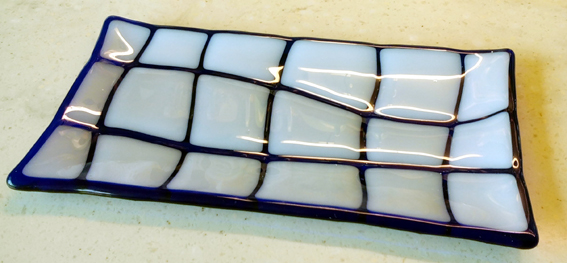

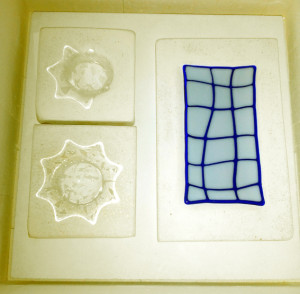

Following on from a fusing run, I slumped the results to make a shallow dish and 2 tea light holders.

The dish slumped perfectly, which is not a great surprise, since it is a shallow run and so has nowhere to go other than into the mould. I think we have perfected this design now.

The key setting was 725 degrees for 30 minutes, which I have adjusted following a few earlier slumping runs to the point where I have a setting that appears to make good shallow dishes and deeper slumping for tea lights.

However, next we move on to a problem with the slumping of the tea light holders. The holder at the front of the kiln didn’t slump enough, it has a rounded base that didn’t reach the kiln floor. Worse was the tea light at the back, as can be seen in the detail pictures below, it slumped unevenly, sinking down unevenly on one side and not the other.

I am a little mystified. I have a few theories, against which I would welcome a critique from those more experienced in fused glass work.

- I have a Kilncare kiln, which is supposed to have (and on fusing runs has proved to have) a good even temperature across the kiln. But is the slumping process too sensitive to run successfully towards the corner. Does this explain why the inside of the top tea light has melted more?

- But, if this is the case then why has the bottom tea light slumped evenly, but not enough, suggesting that it wasn’t hot enough?

- Or could it be that my vermiculite mould is too rough to allow the glass to ‘slide’ down and has caught it on one side? I have checked and this doesn’t seem to be the case, unless again it is extremely sensitive.

If this wasn’t the same setting that was successfully used for the last tea light, I would think that I need to increase the temperature by 5-10 degrees and move the tea lights to be more central in the kiln.

Or am I missing something? Any ideas welcome.

Copied from a message from Kristin at https://idlecreativity.wordpress.com

Hi Andy, A couple of thoughts come to mind. First, I think you are way too hot. For a plate mold like the one on the right, I would stay around 1180 degrees F (638 degrees C). What was happening to mine when I went hotter is that I got a bulge upward in the middle and someone explained that was because as the kiln kept getting hotter, it kept slumping down and pushing the center upward.

As far as the smaller dishes, you are right that the steep slopes of the sides hinder a slump and often you don’t get as wide a body as it doesn’t slump all the way down the steep slides and instead I just wait until I have a large enough flat bottom. I am not sure your ramp, but for most slumps and especially the deeper ones, slow is the way to go. I typically ramp 200-250 degrees F (100-120 degrees C) for slumps. Also for most slumps like the larger plate one, I would only hold for 10 minutes at top temperature. For your smaller deeper ones, though, perhaps try holding slightly longer like 15-20 minutes to start. In deeper molds it is better to hold longer than take hotter.

Lastly, I would run some tests with your kiln probably using clear glass as it is cheapest. Take 2 layers of small squares and place them on your shelf and take them to a full fuse. Take notes before you remove them on if they didn’t all fuse the same where each one was relative to its level of fusing. Kilns should heat evenly but sometimes they don’t and so you just need to get to know your kiln. If the kiln heated evenly it should not matter where you put any piece. If it is really uneven, then I would contact the kiln manufacturer or perhaps where you bought the kiln and perhaps it is time to change the heating coils.

Hope all this helps. You have not made any major mistakes. A big part of fusing is experimentation with temperatures, ramps, holds. Make sure you take good notes regularly as I still rely on my notes from projects in the past (even to answer your question here). Good luck!

Thanks Kristin. The ramp I have is 200 degrees C. That came from a preset on the kiln. Sounds like that might be the key element. I will reset and give that another go. Thanks again, Andy.